Galvanized Coil in UAE | Types, Benefits, and Applications

Are you searching for a galvanized coil in UAE? If yes! You are on the right page.

Furthermore, it is essential to be well-informed and up to date before making a purchase. Before delving into the details, we hope you have heard the term galvanized steel coil numerous times. Nevertheless, have you ever wondered what precisely galvanized coils are? Well! To better understand it, this comprehensive guide covers everything you need to know about galvanized coils.

Send Enquiry

Whether you work in automotive manufacturing, construction, or any other related industries, having a good understanding of PPGI coil UAE is one of the beneficial factors you must know. Moreover, galvanized steel is used in numerous corrosion-resistant items, including pipes, nuts, bolts, balconies, and staircases. Whether you are a buyer or a seller of galvanized coils, this in-depth write-up will help you learn more about steel coils.

What Are Galvanized Steel Coils?

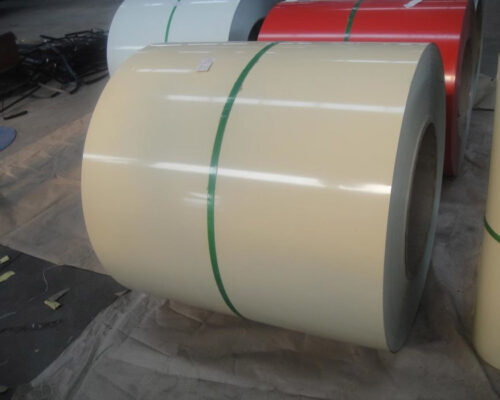

A galvanized or galvanized steel sheet is a steel sheet that has been coated or dipped in zinc to prevent rusting. Galvanized coils are produced by applying a zinc layer through a continuous hot-dip galvanizing process or by immersing steel strips in molten zinc baths. Likewise, the zinc coating serves as an additional protective layer between the steel and its surroundings. It means that if the zinc coating is scratched or broken, the zinc rusts before the underlying steel.

It is often manufactured from low-carbon steel with a carbon content of less than 2%. Nevertheless, this steel coil is picked because it is easy to work with and has exceptional forming and welding properties. PPGI coil UAE depends on the particular characteristics and type of the product. Therefore, galvanized coils can be further differentiated and refined based on multiple components, including specific coating width, thickness, and other product attributes.

What are the Types of Galvanized Coils?

There are two significant types of galvanized steel sheet or coil, differentiated by the zinc-coating process. To know them precisely, read the following pointers that are mentioned below:

1. Hot-Dip Galvanized Steel Coils

Hot-dip galvanized coils are among the most commonly used forms of galvanized coils. Furthermore, a ppgi coil UAE is immersed in a hot-dip bath of molten zinc during the hot-dip process, which forms a metallurgical bond with the external steel surface. Nevertheless, this results in a long-lasting and thick zinc coating with excellent corrosion resistance. Hot-dip galvanized coils are known for their superior rust resistance and are widely used across industries.

2. Electro-Galvanized Steel Coils

In the electro process of galvanized coil in UAE, electrolysis is used to apply a delicate layer of zinc to steel coils. Unlike hot-dip galvanizing, electro-galvanizing does not require immersion in molten zinc. Compared to hot-dip galvanized coils, electro-galvanized coils have a thinner zinc coating. Likewise, they exhibit subtle corrosion resistance and are often used in applications where a thinner coating is sufficient or a smooth, even appearance is required.

What are the Imperative Benefits of Galvanized Steel Coils?

Here are some benefits of using PPGI coil provided by the PPGI coil supplier in UAE. Likewise, when you use it in any construction project, depending on the applications, here is the list of pointers that you will achieve at the end:

1. Protection

Coating of galvanized coil in UAE is considered one of the most difficult coatings in the industry. Therefore, it provides a protective layer against mechanical damage that may occur during the erection or transit of the structure. Also, it secures steel from corrosion and rust. Furthermore, it is suitable for all weather and temperature conditions, so changes in weather do not affect the coil.

2. Durability

Since it adds a protective layer, PPGI coil in UAE prevents rust, corrosion, and weather conditions. However, the risk of steel damage is reduced, resulting in a longer lifespan.

3. Low-maintenance

Galvanized coils offered by the PPGI coil supplier in require minimal maintenance. As a result, your crucial maintenance efforts are saved.

4. Cost-efficient

The initial competitive cost of the galvanized coil in UAE might be high. Nevertheless, you can save on repair and maintenance costs as it is a low-maintenance product. Additionally, coating and layering of zinc on galvanized coils offer durability. Hence, it is cost-effective in the long run.

Application of Prepainted Galvanized Steel Coil in Different Industries

The prepainted galvanized steel coil market is one of the most diversified in the United Arab Emirates. Due to their exceptional endurance, versatility, and corrosion resistance, they are used for the following applications:

1. Construction

A GI coil in UAE is widely used in the construction industry. Furthermore, they are used to make roofing materials, such as standing seam roofs, roof tiles, and corrugated sheets. Additionally, galvanized coils are used to design structural elements, columns, wall panels, and beams.

2. Automobile Industry

Galvanized coil in UAE is used extensively in the automotive industry to make a wide range of components and parts. Frames, reinforcements, structural sections, body panels, chassis elements, and exhaust systems are examples of these. Galvanized steel’s corrosion resistance helps to add a protective layer in automobiles from rust and extends their lifespan naturally.

3. Household Goods and Appliances

Appliances such as air conditioners, ovens, microwaves, refrigerators, and washing machines are usually made from galvanized coils. Additionally, they are used to make tools, cabinets, kitchenware, and other household items.

4. HVAC Systems

PPGI coil UAE is widely used in HVAC systems, including air conditioning and ventilation. Due to their resistance to and longevity in high-moisture environments, they are used to produce vents, air ducts, and other components.

5. Agricultural Machinery

Galvanized coil in UAE is utilized in the agricultural sector to make equipment, such as farming machines, gain silos, fences, and barns. Galvanized steel’s corrosion resistance enhances the dependability and lifetime of this equipment and structures.

It’s Time to Wrap Things Up!

Ultimately, when purchasing PPGI coil in UAE, it is essential to understand parameters, including steel grade, manufacturing process, coating thickness, and supplier reputation. Furthermore, these vital components significantly impact the price and quality of the coil. Moreover, industry standards, certifications, and market demand are crucial factors to consider before purchasing galvanized steel coils. You can make an informed purchasing decision that meets your individual needs by thoroughly researching galvanized coils.

However, if you are searching for a reliable PPGI coil supplier in UAE, look no further than Metal n Machine. We offer a wide range of galvanized coils suitable for various applications across multiple industries. With this precise knowledge, you can move forward with confidence, knowing you have the information you need. So, do not wait any longer. Connect with us today and get your hands on our premium galvanized steel coils.

Frequently Asked Questions

There are numerous types of galvanized steel sheet or steel coils present. However, here we have mentioned the top three popular types of galvanized steel coils, including:

- Hot-rolled Steel Coils

- Coated Steel Coils

- Cold-rolled Steel Coils

Ans: Here are the typical applications of prepainted galvanized steel and coils:

1. Commercial Buildings

2. Fencing

3. Automotive Industry

4. Agricultural Buildings

5. Residential Roofing

6. Industrial Sheds

7. Signage

The result is a thin layer of zinc coating in prepainted galvanized steel coil, which might differ from 7 to 42 μm according to grade, with most galvanized coil products usually having a thick coating of 20 μm (micrometers) of zinc.