Aluminium Coil | Know Its Applications, & More

Aluminium coil is one of the most widely used coils in multiple industries due to its corrosion resistance, lightweight nature, and strength. Moreover, manufacturers of aluminium fabrication in UAE produce top-notch coils for automation, packaging requirements, and the construction industry. Moreover, the average demand and supply of aluminium-rolled products are increasing as several industries prefer cost-effective and durable materials.

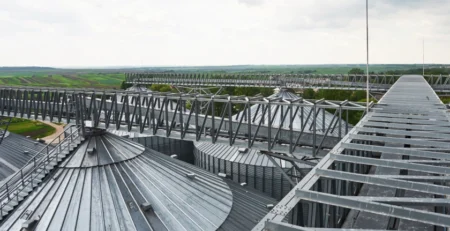

Furthermore, the use of aluminium coil or stainless steel coil in UAE includes roofing, insulation, and cladding in the widely spread construction sector. Similarly, many aluminium coil suppliers provide customization solutions for commercial, residential, or industrial use. These coils are an imperative factor in aluminium fabrication for electrical and transportation equipment. Therefore, industries select aluminium composite panel solutions for modern architectural structures. Likewise, aluminium coil suppliers concentrate on creativity to enhance coil performance and sustainability. However, in this blog, we will discuss the vital uses of aluminium coil, its applications, and more. So, let’s get started!

What is an Aluminium Coil?

An aluminium coil UAE is a flat, long sheet of aluminum rolled up into a spiral or coil form for convenience in storage, transport, and processing. From aluminum bars or slabs, coils are produced in various thicknesses and alloys, which are then processed into sheets, parts, and final products for multiple uses in transportation, construction, packaging, and electronics due to aluminum’s lightweight, corrosion-resistant, and recyclable nature.

Standard Technical Configuration of Aluminium Coil

| Parameter | Specification |

|---|---|

| Material | Aluminium (Alloy Series: 1xxx, 3xxx, 5xxx, 8xxx – depending on application) |

| Thickness Range | 0.2 mm – 6.0 mm |

| Width Range | 20 mm – 2000 mm |

| Coil Weight | 1000 kg – 5000 kg (custom as per requirement) |

| Inner Diameter (ID) | 150 mm, 300 mm, 505 mm (standard core sizes) |

| Outer Diameter (OD) | Up to 2000 mm |

| Temper | O (Soft), H12, H14, H16, H18, H22, H24, H32, etc. |

| Surface Finish | Mill finish, Polished, Coated, Anodized |

| Coating (Optional) | PE (Polyester), PVDF (Polyvinylidene Fluoride), Epoxy |

| Edge Condition | Slit Edge / Mill Edge |

| Density | 2.70 g/cm³ |

| Tensile Strength | 70 – 300 MPa (varies by alloy and temper) |

| Elongation | 5% – 30% (depends on alloy and temper) |

| Conductivity | ~61% IACS (International Annealed Copper Standard) |

| Applications | Roofing, Cladding, HVAC ducts, Automotive, Insulation, Construction, Packaging |

Comparison Table of Aluminium Coil vs Stainless Steel Coil

| Feature | Aluminium Coil | Stainless Steel Coil |

|---|---|---|

| Material Composition | Lightweight, non-ferrous metal (Al, Mg, Mn alloys) | Iron-based alloy with Cr, Ni, and Mo for corrosion resistance |

| Density | ~2.70 g/cm³ (very light) | ~7.85 g/cm³ (heavier) |

| Weight Advantage | Lightweight → easier handling & reduced structural load | Heavyweight → requires stronger structural support |

| Corrosion Resistance | Naturally forms an oxide layer; good in atmospheric & marine conditions | Excellent due to chromium & nickel content; highly resistant to rust & chemicals |

| Strength | Moderate tensile strength (70–300 MPa depending on alloy & temper) | High tensile strength (500–1200 MPa depending on grade) |

| Durability | Good, but softer and more prone to dents & scratches | Extremely durable, tough, and impact-resistant |

| Thermal Conductivity | High (~205 W/mK) → excellent for heat dissipation (HVAC, insulation) | Low (~15 W/mK) → retains heat longer (useful in industrial/structural applications) |

| Electrical Conductivity | High (~61% IACS) → suitable for electrical & power applications | Very low (~3% IACS) → not suitable for electrical applications |

| Magnetic Properties | Non-magnetic | Can be magnetic or non-magnetic (depending on grade, e.g., 304 non-magnetic, 430 magnetic) |

| Surface Finish | Mill finish, polished, anodized, painted, coated (PE/PVDF) | 2B, BA, No.4, Mirror finish, hairline, brushed |

| Maintenance | Requires a protective coating in harsh industrial conditions | Low maintenance, naturally resists staining and oxidation |

| Workability | Easy to cut, bend, weld, and machine; softer for fabrication | Harder to cut & machine; requires special tools |

| Cost | More cost-effective, especially in bulk | More expensive due to alloying elements (Ni, Cr, Mo) |

| Applications | Roofing, cladding, HVAC ducts, insulation, packaging, automotive, and decorative uses | Construction, kitchen equipment, medical, chemical plants, and structural frameworks |

| Recyclability | 100% recyclable with minimal energy consumption | 100% recyclable, but with a higher processing cost |

| UAE Market Preference | Popular for lightweight cladding, roofing, HVAC, and industrial sheet applications | Preferred in architectural projects, chemical plants, the food industry & structural uses |

Application of Aluminium Coil in Different Industries

Here, we have mentioned the fundamental applications of aluminium coil in multiple industries, which are more applicable than stainless steel sheet in UAE:

1. Building and Construction

Aluminium coil is a universal material used in various building and construction projects, from interior decoration to exterior cladding. Being lightweight yet strong, it makes a great universal material for a wide range of applications, including roofing materials, window frames, and facade panels, among others. Its overall durability makes the aluminium coil ideal for a whole range of outdoor and indoor projects.

2. Transportation

Aluminium coils are gaining prominence in transport because they are light and corrosion-resistant. Therefore, they are ideal for vehicle manufacture as they contribute very little weight while providing excellent structural strength. Additionally, aluminium coil UAE significantly lowers noise levels and acts as a shield against environmental conditions such as rain, snow, wind, and road dirt.

3. Electrical and Electronics

Aluminum Coil has numerous uses in the electrical and electronics industries. It is malleable, light in weight, and corrosion-resistant, making it suitable for domestic appliances, electronic parts, switchgear enclosures, motor insulation, and transformers. It also facilitates quick heat transfer to achieve efficient cooling systems.

4. Consumer Goods

Aluminium coils are widely used in the production of household consumer items, including toys, packaging materials, and kitchenware. The ability of aluminium to withstand corrosion has made it a popular material for packaging food products. Manufacturers use aluminium fabrication in UAE to create cans, bottles, and wrapping foil packaging, with the inherent shaping ability of the material making it a top pick for creating kitchenware and other household items.

5. Industrial Applications

Aluminum coils find numerous applications in industries. They are utilized as sheet metal for industrial equipment, such as air conditioning and ventilation systems, containers, and storage tanks. Due to its malleability, it is well-suited for the fabrication of complex components without the need for welding or joining operations.

It’s Time to Wrap Things Up!

We hope this blog has provided you with all the precise details about aluminum coils. Furthermore, if you are searching for the best manufacturer of aluminium fabrication in UAE, look no further than Metal N Machine. We offer a wide range of coils that are perfect for various applications across different industries. Whether you require aluminium or stainless steel, we provide top-notch coil fabrication. However, no need to stress if you want your coil to be a specific size or dimension because at Metal N Machine, we provide customization services that will cover all your needs and preferences. So, what are you waiting for? Connect with us today.